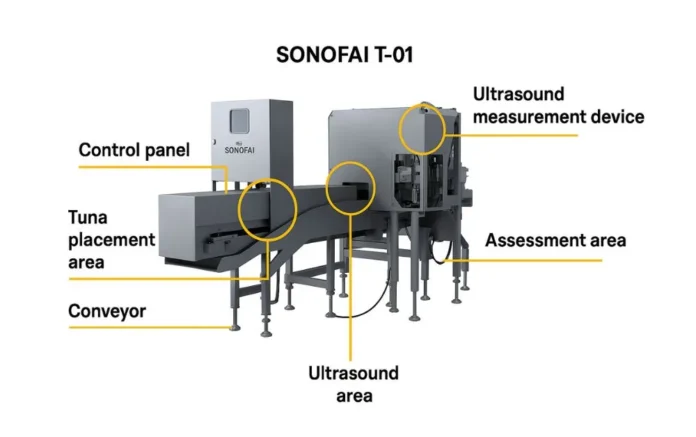

The SONOFAI T-01 device enables rapid frozen tuna inspections which occur without requiring any physical penetrating of the product. The SONOFAI T-01 serves as the product of collaborative development between Sonofai Inc., Fujitsu Limited, Ishida Tec Co., Ltd., and Tokai University. SONOFAI T-01 employs Fujitsu’s artificial intelligence (AI) alongside ultrasound technology to evaluate the fat content present in frozen albacore tuna. Workers can evaluate tuna quality by using the device while maintaining frozen fish preservation.

Why is this important?

The present tuna quality evaluation process involves experienced workers using a knife to cut off tuna tails before visually examining their interior. Training along with experience and skill are necessary prerequisites to conduct this type of work because few employees receive these qualifications. Through its SONOFAI T-01 device automation replaces this current procedure. A technician can operate this equipment to inspect one tuna in 12 seconds automatically. The device reduces work costs at the same time as decreasing inspection time while delivering precise quality results.

How does it work?

The machine executes ultrasound examinations that correspond to medical hospital scanners to analyze the tuna. The AI technology from Fujitsu utilizes the collected data to determine the fat content of the fish. Proper sorting of fatty tuna parts requires attention because their higher price value drives the need for correct identification. The device improves sorting efficiency while ensuring reliability in the process.

Who helped make it?

The development of this project was headed by Sonofai Inc. who operate as a Japanese startup company.

- Fujitsu provided the AI technology.

- Ishida Tec built the machine.

- The research and testing on tuna at Tokai University provided support to the project.

A test operation of the device occurred at Toyo Reizo Co., Ltd. during 2024. The experiment led to outstanding results by showing improved sorting precision when compared to standard tail-cutting procedures.

What’s next?

Sonofai aims to advance the product by implementing checks for fish freshness and texture as well as weight and size measurements. The company maintains plans for the technology to handle different types of fish. The innovative inspection tool holds potential to enhance global seafood company operations in fish evaluation and sorting tasks.

Why it matters:

This innovative tool assists the seafood business by resolving workforce deficits and meeting expanding consumer expectations for premium tuna products. The device enables businesses to locate expensive tuna which had previously escaped detection.

Local leaders from Shizuoka Prefecture supported the project through their Marine Open Innovation Project as they believe it will establish a stronger sustainable fishing industry.